Tapis métalliques à barres entrelacées – Groupe 700

Properties of the belts

- Belts with interlaced bars have a very large open area, and thus nearly unlimited penetration of air, liquids or coating materials.

- Small dead weight.

- The belt consists of just one level, therefore low risk of blinding, as well as good cleaning possibilities.

- All round grooved end rollers allow smooth belt guidance.

- Toothed rollers enable a form-locking drive.

- Return on very small radius is possible.

- Very smooth-running.

Dimensions & materials

Materials:

Possible belt edges and other applications

Standard values for belt edge width:

| Wire diameter in mm |

Belt edge (AK) S in mm |

Belt edge (AK) B in mm |

|---|---|---|

| 0,90 | 3,60 | 6,10 |

| 1,00 | 3,50 | 6,00 |

| 1,25 | 4,20 | 7,70 |

| 1,40 | 4,60 | 9,20 |

| 1,60 | 4,90 | 9,40 |

| 1,80 | 5,20 | 9,20 |

| 2,00 | 7,00 | 13,00 |

| 2,35 | — | 13,60 |

| 2,80 | 8,20 | 13,20 |

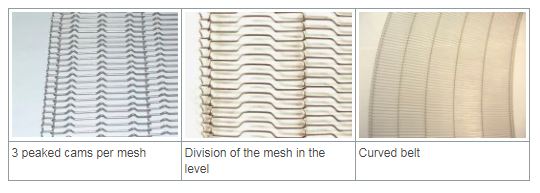

- Belts with interlaced bars can be provided with cams or troughs in different forms as scrapers, spacers or supports.

- Division of the mesh length through additional bends, which results in a larger supporting area.

- Formation of curved belt for different radii.

Possible applications

- Feeding, further conveying and delivery

- Coating machines

- Baking ovens

- Crumb machines

- Fryers

- Cooling tunnel

- Packaging machines

- Spraying and varnishing machines

- Driers

This listing mentions only the most frequent application

Téléchargement

Contactez nous

Demandez votre demande de produit